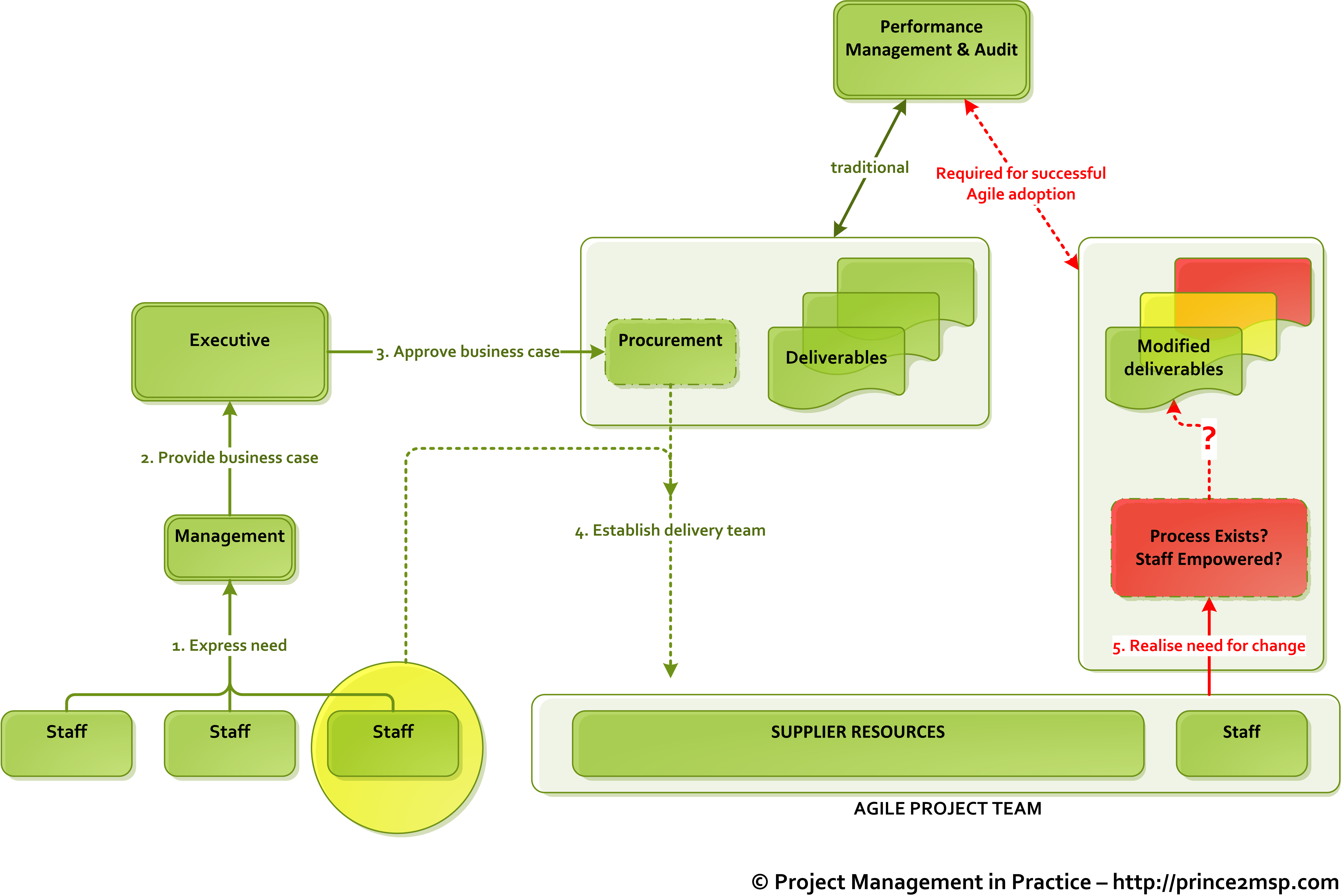

There are companies all over the world that offer a package of procurement service. They restrict the manufacturers to supply and support their instrument. They do not outsource competitive or third-party products to meet the specification of the project. The company’s impartiality and flexibility enable the product to specify, support, source, and supply. It is from the suppliers for meeting the project on time. They have an agreement with reputable manufacturers in the industry. They serve lower pricing than the competitive manufacturers to the customers.

Benefits of procuring

- There is a single point of contact with all the instruments throughout the project life.

- There are manageable sub-suppliers.

- Reduce costs.

- They consolidate the supply of documentation and control of the instruments.

- Manages and coordinates inspection and performs acceptance testing.

- They consolidate the shipment.

- Optimizes the selection of instruments that the engineers back up.

- They manage the regular status reports of the project and project meetings.

- They extend the instrument’s warranty option.

- There is an electronic interchange of documentation.

- Installation services, commissioning services, and maintenance services.

They use the traditional method of instrumentation procuring. It is for the project or application for raising the purchase order with the manufacturer directly. The project includes the instrumentation from various manufactures they consider raising the cost for a purchase order. They manage different sub-suppliers, which is time-consuming and challenging logically. The project agreement and its terms and conditions involve legal personnel. Package procurement specifies and procures control and instrumentation from a single supplier. So, they reduce the cost, streamline the project, and save time while managing the product. The growth and emerging number of engineers and construction contractors are moving towards fulfilling the project requirement and owes to savings.

Selecting suitable technology

the technology that the application uses depends on its suitability and reliability. Different technologies provide equal solutions, and choosing from them is a challenge. It is necessary to understand the technology before selecting one. When the company gets an inquiry, the engineers cross-check their specifications and confirm that they are suitable for the particular application. They recommend the economical and fit solution, regardless of the manufacturer following the specification of the application. See here they bring the attention of the customer for the remedial action. The two parties agree upon the terms and conditions of the project for saving the legal resource. The company enters the details of the project on the developing manufacturing system. They place the order in sub-suppliers and monitor their performance. They arrange a meeting at this stage to agree upon the milestones of the project.

Sub-suppliers management

Throughout the project lifecycle, the company will monitor and manage each sub-supplier to ensure there is no slippage on the lead-time original quote and avoid the potential problem. The communication relies back upon the customer in the form of a status report of the project. They work with any sub-supplier that the client specifies or the application for meeting the project requirements.

Control of documentation

For running the project smoothly, document control should be efficient. Specifically, require the management of multiple suppliers of equipment. The document of supplier register is a hub for ensuring that they achieve the submission, final acceptance, and approval on time. With the help of the in-house contract department, they handle the documentation requirements. These are from the CAD drawings to the dossier translation to any language. They treat the documentation and instruments equally. Documents are subject to the same quality audit and review. According to the client’s preference, they transmit the documentation from the sub-suppliers directly with the copies to the company’s contract team.

Filtering the review is necessary to ensure that the personnel of the client saves time. They do not have to review the wrong or incorrect format of the documentation. The filtering consolidates or recreates the documentation to meet the standards before the submission. They use electronic document transmission in the approval stage to ensure that they efficiently carry transfer and review.

Project management

The management prefers quality procedures. The purpose of the document is to highlight the approach and actions they implement to optimize the contract. The order placement, presentations for creating awareness, and stress are necessary for the instrumentation procedure. They supply goods by inspecting and testing under a contract. The testing facilities determine instrument testing and calibrating at the locations. The company carries our final inspection for the documentation before shipping. For completing the project, the mobile services and the commissioning team installs and maintains the instrumentation. The engineers deliberately involve 24 hours to the contract.

Sum up

Organizing inspections, expediting documentation, acceptance tests of the factory, and coordinating the deliveries from various vendors are an example that contributes to the project management. So, you can see here that they try to reach the right person while dealing with multiple suppliers. The project management team of the company enables the customers to reduce the costs. They can have a single point of contact with one supplier for the project lifecycle. They provide great flexibility and neutrality in order of product specification. They prefer independent bases to procure, identify, and supply the instrument. The instrument vendor allows management and coordination of the sub-suppliers for providing professional service. They deliver according to the requirement of the customers. The procedure ensures that they monitor the aspects of the chain of supply closely to avoid delays.